Types of heat pump

LiBr heat pumps are used to raise waste heat from a low temperature level to a usable level. Under suitable conditions, an ROI can be achieved within one to two years.

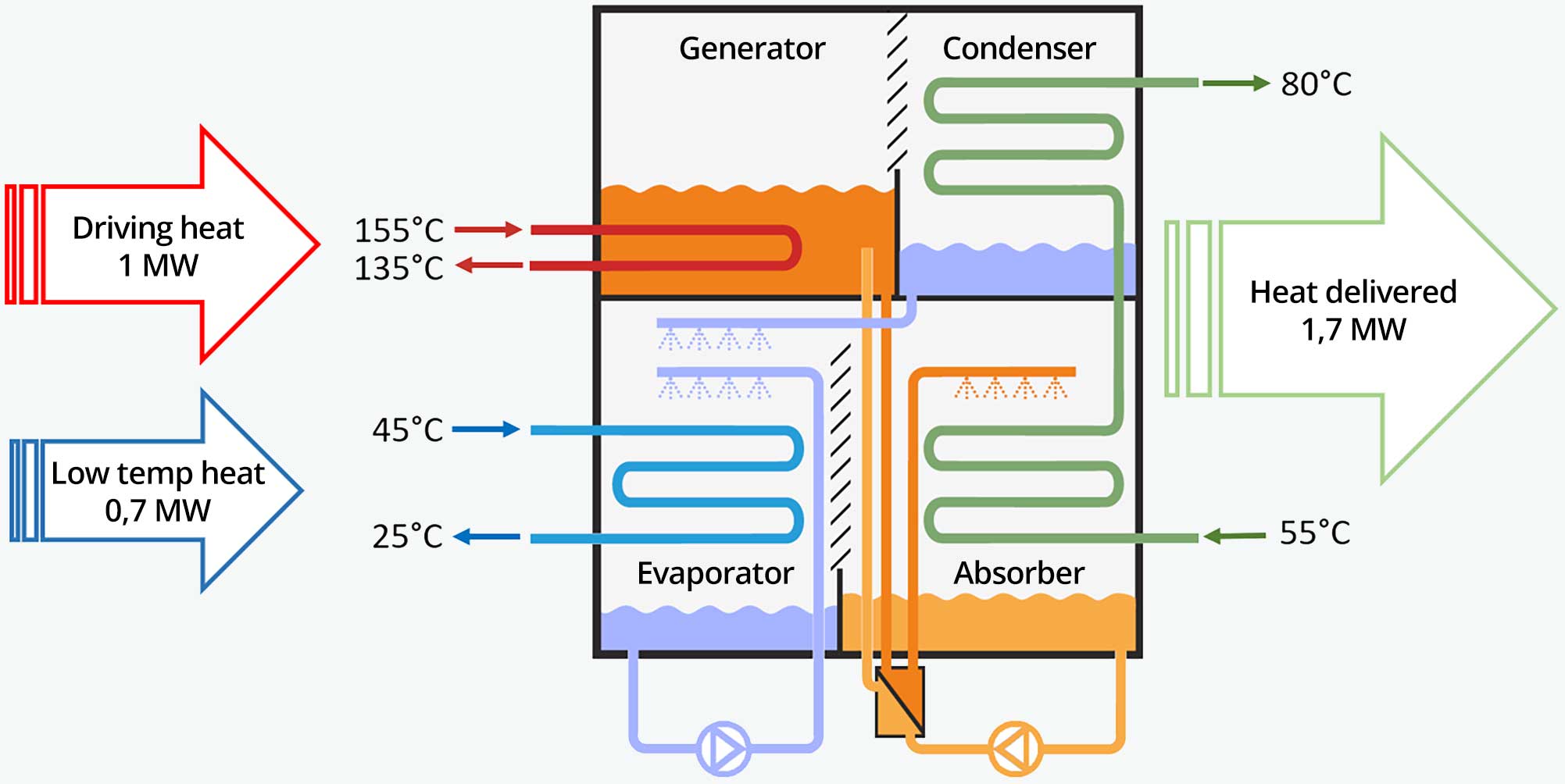

Single-stage heat pump

This is by far the most frequently used configuration for heat pump applications and currently covers about 90% of all projects.

Since 2023, STEPSAHEAD is realizing projects with Absorption Heat Pumps using 105°C hot water as driving energy in specific cases. This is of special interest for biomass heating plants in a range of approx. 1-4 MW heating capacity as normal warm water boilers can be used, avoiding steam or pressurized hot water boilers.

The most important fields of application are:

- Support for district heating from combined heat and power plants with various fuels

- Flue gas condensation in biomass or gas boilers despite high return temperatures in the heating circuit

- Use of various low-temperature sources in industry, e.g. waste heat that is otherwise released into the environment via cooling towers

Technical data (guideline values)

Driving temperature

(generator)

Flow: 120°–170°

Return: 10–15 K lower

Medium temperature

(absorber + condenser)

Flow: 75°–90°

Return: 20–35 K lower

Low temperature

(evaporator)

Flow: 30°–50°

Return: 10–20 K lower

COP

(COP = Q useful / Q input)

approx. 1.7

Driving temperature

(generator)

Flow: 120–170°C

Return: 10–15 K lower

Medium temperature

(absorber + condenser)

Flow: 75–90°C

Return: 20–35 K lower

Low temperature

(evaporator)

Flow: 30–50°C

Return: 10–20 lower

COP

(COP = Q useful / Q input)

approx. 1.7

Double-lift heat pump

This type of machine allows the use of low-temperature waste heat sources. With this type of heat pump, 10°C on the cold side and 85°C on the heat output side can be achieved.

Specification (example)

Driving temperature

(generator)

Flow: 170°

Return: 160°

Medium temperature

(absorber + condenser)

Flow: 85°

Return: 57°

Low temperature

(evaporator)

Flow: 20°

Return: 10°

COP

(COP = Q useful / Q input)

approx. 1,3

Driving temperature

(generator)

Flow: 170°C

Return: 160°C

Medium temperature

(absorber + condenser)

Flow: 85°C

Return: 57°C

Low temperature

(evaporator)

Flow: 20°C

Return: 10°C

COP

(COP = Q useful / Q input)

approx. 1.3

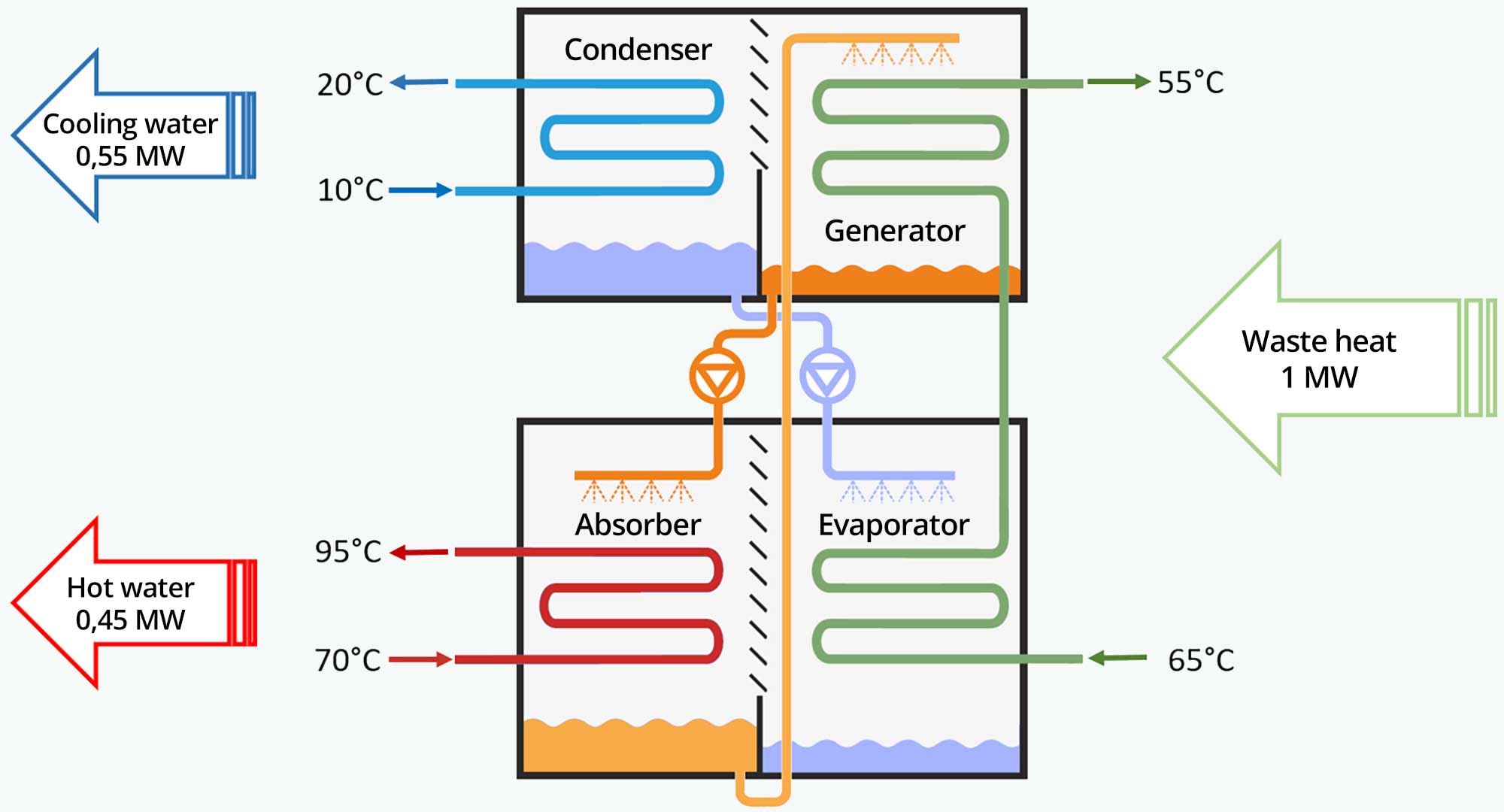

Double-stage low temperature heat pump

At approx. 2.4, this configuration achieves the highest coefficient of performance (COP) of the absorption units presented here. It can be used for installations in which the required output temperature does not exceed 55°C.

Technical data (guideline values)

Driving temperature

(generator)

Flow: 170°C

Return: approx. 10 K lower

Medium temperature

(absorber + condenser)

Flow: 50–55°C

Return: 20–30 K lower

Low temperature

(evaporator)

Similar to single-stage

COP

(COP = Q useful / Q input)

approx. 2,4

Driving temperature

(generator)

Flow: 170°C

Return: approx. 10 K lower

Medium temperature

(absorber + condenser)

Flow: 50–55°C

Return: 20–30 K lower

Low temperature

(evaporator)

Similar to single-stage

COP

(COP = Q useful / Q input)

approx. 2.4

Category 2 heat pump

This heat pump type is used when waste heat at a lower temperature level cannot be used, but heat at a higher temperature can.

As for most absorption units, the driving energy source is heat. Electrical energy is used only for auxiliary apparatus such as pumps.

However, about half of the heat used is released into the environment as waste heat.

Technical data (guideline values)

Driving temperature

(evaporator + generator)

Usually 30–40°C below the usable heat

(high temperature)

High temperature

(absorber)

max. 155°C

Depending on available energy source temperature

Low temperature

(condenser)

Usually 30–40°C lower than the driving temperature

COP

(COP = Q useful / Q input)

Approx. 0,5

Driving temperature

(evaporator + generator)

Usually 30–40°C below the usable heat

(high temperature)

High temperature

(absorber)

max. 155°C

Depending on available energy source temperature

Low temperature

(condenser)

Usually 30–40°C lower than the driving temperature

COP

(COP = Q useful / Q input)

approx. 0.5