References

Plants

Biomass heating plants

Absorption heat pumps are utilized in biomass heating plants to cool the flue gas well below its dew point and to raise the temperature of the heat recovered from the condensation process to a level usable for district heating networks. The heat used to drive the system and the recovered waste heat are simultaneously supplied to the district heating network. Compared to a boiler without heat recovery, this system typically generates 20-30% more energy from the same amount of fuel.Improvement of fuel utilization with ECO and active condensation by up to 49%! (measured by the customer, December 2020)

Commissioning: October 2020

Driving energy: Hot water 150°/130°C (1.15 MW)

Flue gas condensation: 32°/22°C (0.85 MW)

District heating supply: Return flow temperature increase 55°/70°C (2 MW)

Similar to Wagrain, but with a relatively high return temperature due to a commercial heat consumer in the network.

Commissioning: February 2022

Driving energy: Hot water 150°/125°C (0.7 MW)

Flue gas condensation: 32°/26°C (0.5 MW)

District heating supply: Return flow temperature increase 59°/72°C (1.2 MW)

The first active flue gas condensation system with an absorption heat pump driven by only 105°C hot water from a boiler. After evaluating the first heating season 2023/2024, an additional 26.2% of the heat generated by the boilers was recovered through ECO and flue gas condensation!

Commissioning: July 2023

Driving energy: Hot water 105°/95°C (0.95 MW)

Flue gas condensation: 45°/35°C (0.76 MW)

District heating supply: Return flow temperature increase 52°/68°C (1.71 MW)

Info will be posted after commissioning.

Info will be posted after commissioning.

Info will be posted after commissioning.

Combined heat and power plants

In combined heat and power plants, simulations of the entire system are necessary to responsibly assess the impact on electricity production, the supply to potential process steam consumers, and hot water production under different load conditions. These simulations are conducted at StepsAhead using Ebsilon (www.ebsilon.de).Following the successful Klagenfurt East project, the combined heat and power plant at this location was also retrofitted with active flue gas condensation, improving fuel utilization by approximately 20%.

Heat output: 12.7 MW

Commissioning: January 2018

Driving energy: Hot water 130°/120°C

Flue gas condensation: 45°/35°C

District heating supply: Return flow temperature increase 60°/80°C

Industrial waste heat utilization

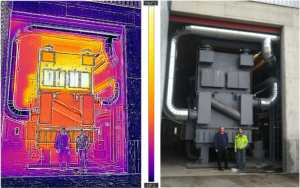

In industrial projects, it is particularly important to analyze and, if necessary, simulate not only the absorption heat pump but also the affected industrial environment. These simulations are conducted at StepsAhead using Ebsilon (www.ebsilon.de).This absorption heat pump is driven by hot air at 400°C. It is used to recover waste heat from the moist exhaust air of the dryer.

Heat output: 3.8 MW

Commissioning: Q1 2018

Process data is not disclosed for this project.

This absorption heat pump recovers heat from an industrial condensate and makes it available for district heating in the city of Graz. It is a custom design adapted to the small technical room at a height of 12 meters.

Heat output: 7.3 MW

Commissioning: Q4 2023

Driving energy: Saturated steam at 3.8 bar_a

Waste heat: 56°/46°C

District heating supply: Return flow temperature increase 68°/93°C

Planning

STEPSAHEAD always supplies each customer with the detailed design of the heat pump for the nominal operating point and, on request, produces characteristic diagrams for the customer’s entire operating ranges.

Simulations of the overall system with heat pump have, for example, been created for the following customers/sectors:

Biomass boilers, district heating, cogeneration power plants

- Nahwaerme.at

- Bioenergie Köflach

- Waste power plants

- Waste wood power plants

- Wien Energie

- Dalkia

- Vattenfall

- etc.

Waste heat utilisation:

- Paper industry

- Building materials industry

- Gas engine CHP plants

- etc.